How to get Six Sigma certification to grow your career? The trick is to pick the right certification — one that matches both your knowledge and the recognition hiring managers look for.

This is the approach that helped me gain both the skills and the recognition when I had no clue about Six Sigma.

The White Belt is not covered in this article. As an introductory level, it holds no significant career impact.

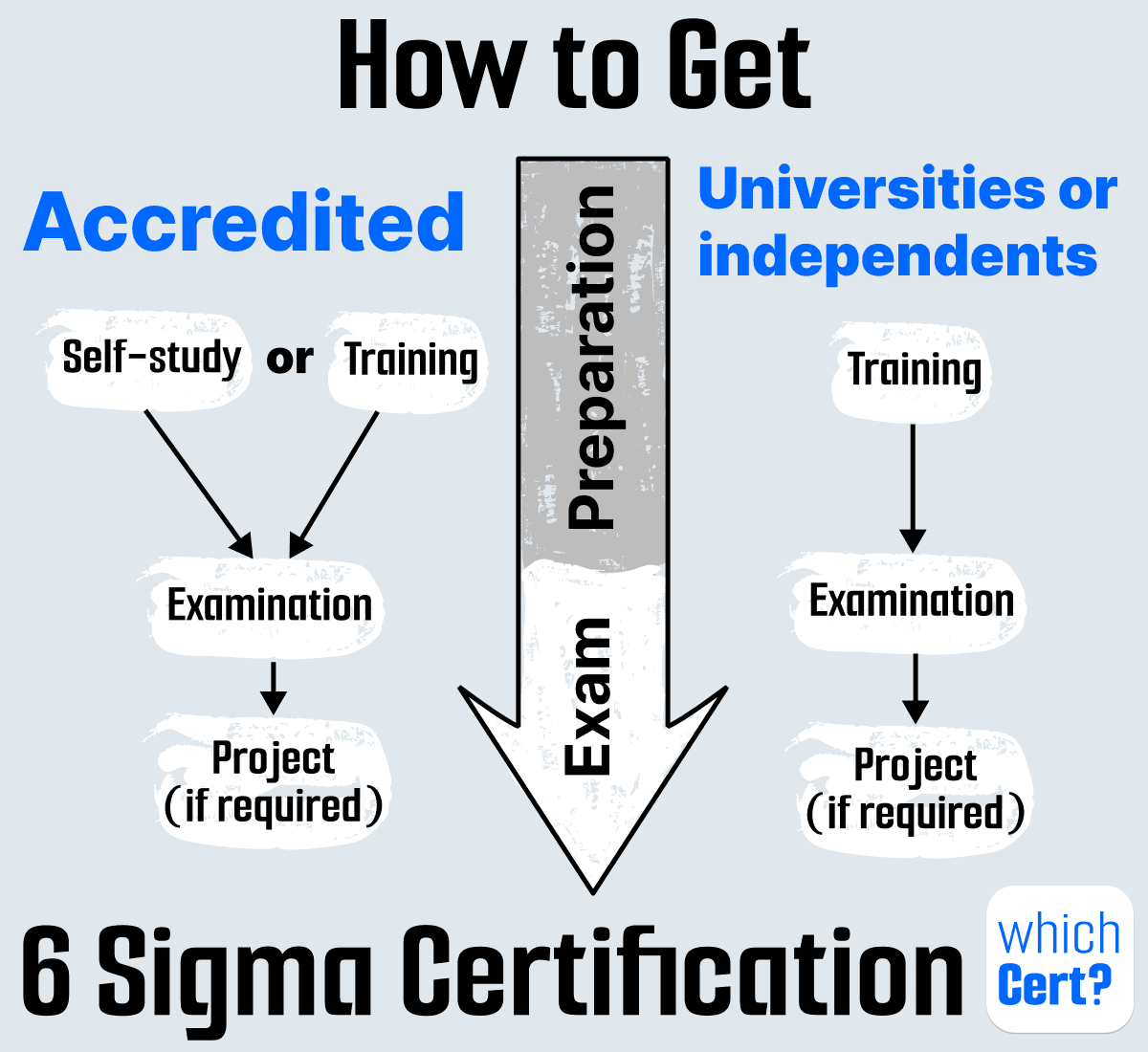

Step 1: Select the certification type (ASQ vs IASSC vs CSSC vs universities vs independent providers)

Three main types of providers offer Six Sigma certification:

- Accredited certification providers, usually recognized by one of these bodies:

- ASQ (American Society for Quality)

- IASSC (International Association for Six Sigma Certification)

- CSSC (Council for Six Sigma Certification).

- Universities (mostly online programs)

- Independent certification providers

An accreditation body is an organization that checks and approves certification providers to make sure they meet strict standards. It’s not the same as a certification provider, though some accreditation bodies also offer certifications directly.

Want to understand what accreditation really means? Check out our beginner-friendly 5-minute guide here: What Is Accreditation?

I suggest focusing on three main points before choosing a Six Sigma certification:

- Recognition of the certification: Check how employers and industries view it. Not all Six Sigma certifications carry the same weight Learn how to identify the most recognized Six Sigma credentials.

- Depth and content of the program: Some courses are complete and detailed; others are quite basic. Make sure the one you choose covers key topics like the KANO Model, Poka Yoke, and Design of Experiments (DOE) — these tools can make a big difference in your career.

- Cost and value for money: Prices vary widely. Choose a certification that fits your budget while offering solid learning and career value.

Avoid hidden fees — see the full Six Sigma certification cost guide

Step 2: Select the belt level

Next, based on your choice in Step 1, determine which belt level (for example, Yellow, Green, or Black) is realistically achievable by comparing the certification requirements set by CSSC, IASSC, and ASQ. This comparison also takes into account options offered by independent providers and universities.

If you are eligible for both the Yellow Belt and the Green Belt, the Green Belt is generally the better option, as it is more commonly requested and recognized by recruiters.

Get the info you need to choose between Lean Six Sigma and Six Sigma in Lean Six Sigma vs Six Sigma: Which is Better?

Step 3: Choose your training method (self-study or online training)

a- Self-study option:

Self-study is most effective when preparing for accredited certifications. For non-accredited certifications, studying on your own can be risky because each provider may follow different rules or define their own “Body of Knowledge,” which is often not publicly available. As a result, the Lean Six Sigma books you use might not align with what their exams actually test.

If you’re looking for reliable books that align well with recognized Lean Six Sigma certification paths, check out my detailed guide to the best Six Sigma self-study books — it will help you choose resources that match real exam expectations.

You can also support your learning with free Lean Six Sigma online courses. For example, the edX course “Lean Six Sigma Yellow Belt: Quantitative Tools for Quality and Productivity” from TUM (Technical University of Munich) is very rich and interesting, and it covers many topics found in the ASQ Green Belt Body of Knowledge. You can audit it for free, meaning you can access the full content without paying for a certificate.

b- Paid training option:

If you prefer structured learning or need extra help with complex topics, enrolling in an online training course can provide valuable guidance and better prepare you for the certification exam.

The advantage of Universities’ programs and other independent online providers is that you do not have to choose between self-studying and enrolling in the training, since training is a part of the certification requirement. Universities’ programs also tend to be more comprehensive and academic (longer), offering deeper insights into Six Sigma and quality management concepts.

Start your Lean Six Sigma Yellow Belt journey today to build a solid, recognized skill set—or explore our top Green Belt training programs with certification.

Step 4: Take the Six Sigma certification exam

If you completed your training with a center that offers accredited certification, make sure their credentials match the accreditation body you selected in Step 1. If they do, you can go ahead and register for the exam.

If you studied independently or your training provider doesn’t offer certification, you’ll need to find a certification provider to register for the exam through them, and complete any required project work, if applicable (see requirements).

Step 5: Maintain your Six Sigma certification (if required)

Some Six Sigma certifications require periodic renewal or continuing education to remain valid. Be sure to review the certification expiration.

The recertification process may include earning Professional Development Units (PDUs), retaking exams, or completing refresher courses.

Staying current ensures your certification continues to support your career growth.

Final thoughts

How to get Six Sigma certification involves going through the following steps:

- Step 1: Select the certification type (ASQ vs IASSC vs CSSC vs universities vs independent providers)

- Step 2: Select the belt level

- Step 3: Choose your training method (self-study or online training)

- Step 4: Take the Six Sigma certification exam

- Step 5: Maintain your Six Sigma certification (if required)

Finally, choose the Six Sigma certification path that truly reflects your skills and helps you gain the recognition you deserve for future career growth.

FAQ

What is the fastest way to get Six Sigma certified?

Choose an independent online provider that offers a lightweight program and does not require project completion.

How to get Six Sigma certification cost?

Six Sigma training and certification exams don’t have a convergent price across all levels. Costs range from $499 for access to all GLSS trainings and certifications to $422 for only the Yellow Belt exam fee from ASQ. The price mainly depends on your career objectives.

Can I learn Six Sigma on my own?

If you already have experience in quality engineering, many programs will be relatively easy for you—especially if you’re strong in statistics. However, if you’re new to the field, I recommend starting with a MOOC that offers a more comprehensive curriculum.

Is the Six Sigma white belt free?

Yes, the Council for Six Sigma Certification (CSSC) offers a free Six Sigma white belt certification.